Widely Use Of YIXIN Automatic Pipe Welding Machine

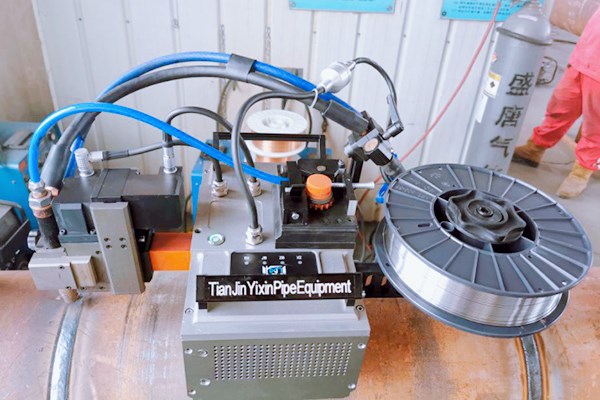

Automatic welding equipment is widely used in flange welding, straight seam welding, and air conditioning pipe welding.

YIXIN automatic welding machine is not only suitable for pipe and tube welding, but also for flange welding, flat welding, and straight seam welding. It is not only suitable for land and underground pipeline welding, but also widely used in high-altitude welding such as air-conditioning pipes. In addition, it is also suitable for welding of various wall thicknesses, as small as 5mm and as large as 100mm can achieve perfect welding. It is a very widely used welding equipment.

Super-thick Pipe Welding

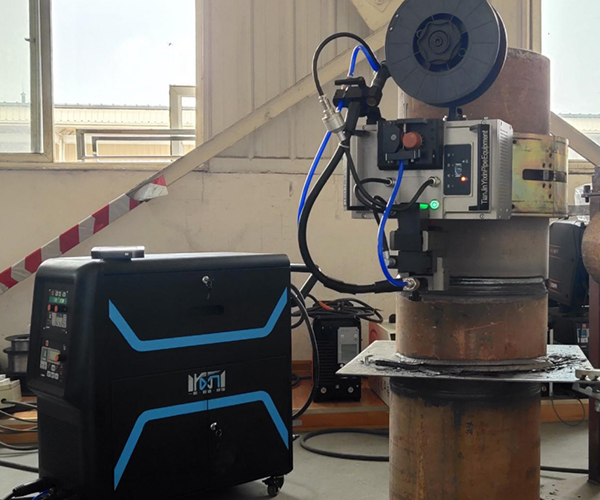

HW-ZD-200 Used To Weld 85mm Thick Pipe With 100% Pass Rate

As the top product of YIXIN, HW-ZD-200 was used for welding super thick pipes with 85mm wall thickness and achieved perfect results. It is a breakthrough success for thick wall welding at home and abroad.

In June 2020, a comprehensive renovation project of a certain southern river area entered emergency preparations. The bottom shaft of its driving flap gate was an super thick pipeline with a diameter of 2000mm and a wall thickness of 85mm. The welding project became a major problem in this project, and it is obviously that solving this problem has become the top priority at the moment.

After many inspections, the client has a great interest in our company's HW-ZD-200 pipeline all-position intelligent welding machine.

The Product Quality Standards Institute of the Ministry of Water Resources organized a special meeting with relevant experts from all contracting companies of the project to conduct an in-depth discussion on the feasibility of the welding method of the all-position intelligent welding machine, and finally decided to use YIXIN's HW-ZD-200 equipment to conduct welding test and welding procedure qualification data collection.

This super thick pipe wall welding test was a complete success. Under high-strength operating conditions, the HW-ZD-200 is operated smoothly and well, without any adverse reactions such as high-heat interruption failure warnings, and minimal operator intervention. After the test welding, under the witness of the customer, we invited a professional third-party inspection company to conduct the welding bead quality inspection, and successfully passed the ultrasonic and phase resonance non-destructive inspection. Finally, the customer purchased our company's HW-ZD-200 equipment as the welding equipment for this project.

The project was officially launched on August 1, 2020, and the welding pipe diameter specifications are DN2000*70mm and DN1500*80mm. The welding was completed in mid-October, and the project is still ongoing. The completed welds are tested for flaw detection. Up to now, the test results have a high pass rate and have been unanimously approved by the owner and the construction party.

Thick Pipe Welding

Straight Welding

Noromal Pipe Welding

Flange Welding